Decom

is expertly mitigated.

Over the last 30 years we've built a track record of successful decommissioning work on over 300 wells:

- Phase 0 Well Integrity Verification

- Surface and thru-tubing monitoring, maintenance, upgrade and remediation

- Plug and barrier setting

- Isolation verification

- Removal of Xmas trees and tubing hangers

- Installation of suspension flanges.

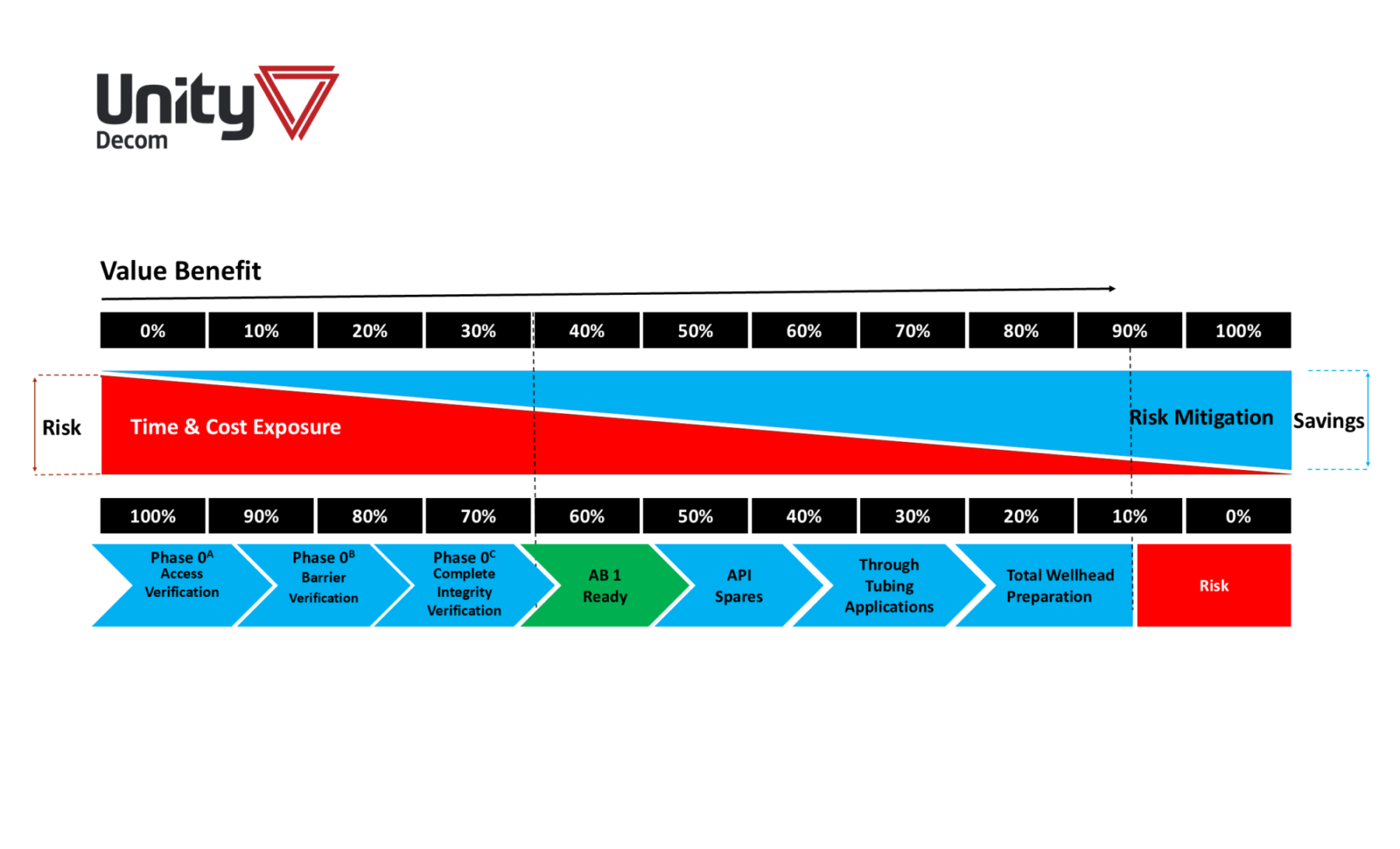

P&A Phase 0 - Knowing you're well prepared

Phase 0 Well Integrity Verification is a crucial preparatory undertaking for operators looking to avoid unplanned downtime, cost overruns and added risk during P&A operations. It provides a full health check of your wellhead and inwell equipment prior to P&A operations and informs and derisks the entire decom process.

Thru-Tubing Services

Following preparatory Phase 0 work, our downhole, thru-tubing services support Phase 1 well abandonment operations.

We supply a suite of specialised tooling, plugs and services for:

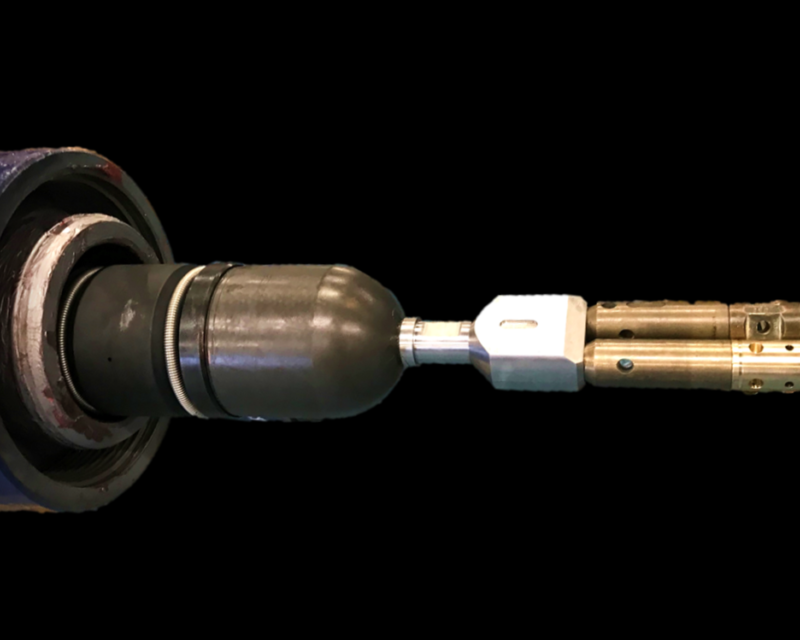

- Installation of standard and high expansion cement retainers

- Cement barrier installation tooling

- Contingency cement milling

- Integrity inspection, leak detection and remediation

- Engineered solutions

The Complete Decom Package

Review of existing infrastructure and interface requirements. detailed surveys of Xmas tree, wellhead and production air-gapping requirements.

Pre-planning of workscopes, identifying contingencies, method statements and procedures. close out reports, morning calls, input to campaign planning and maintaining action register.

Management of logistics, equipment and personnel, workshop activities. equipment supply and certification. 3rd party rentals and cost management.

Digital Well Tracking – Access to our North Sea Digital Well Tracking System which maps physical equipment attributes. This has been built from Unity’s years of experience combined with historical open source slot data. Particularly useful for decommissioning or remediation decision making to understand legacy well configurations.

Valve integrity testing and remediation, flowline removal and air-gapping, installation of blind flanges. flushing and stinging operations.

Phase 0 Wellhead Integrity Verification.

Internal inspection of the Xmas Tree and hanger with memory caliper or camera.

Xmas Tree and wellhead pressure and integrity testing, service/replace critical valves. pressure monitoring of annuli, echometer monitoring of tubing and annuli fluid levels, annulus top ups, annulus valve and instrumentation removal, installation of kill valves, hot bolting

Thru-Tubing Intervention and Remediation Services

Plug and cement barrier setting

Casing cutting, milling through inoperable gate valves or other near surface blockages. Scraping, brushing, debris and swarf removal.

Riser tensioning

VR plug installation, install / retrieve tubing hanger plugs and near surface bridge plugs

Provision of plugs and running /retrieval tools.

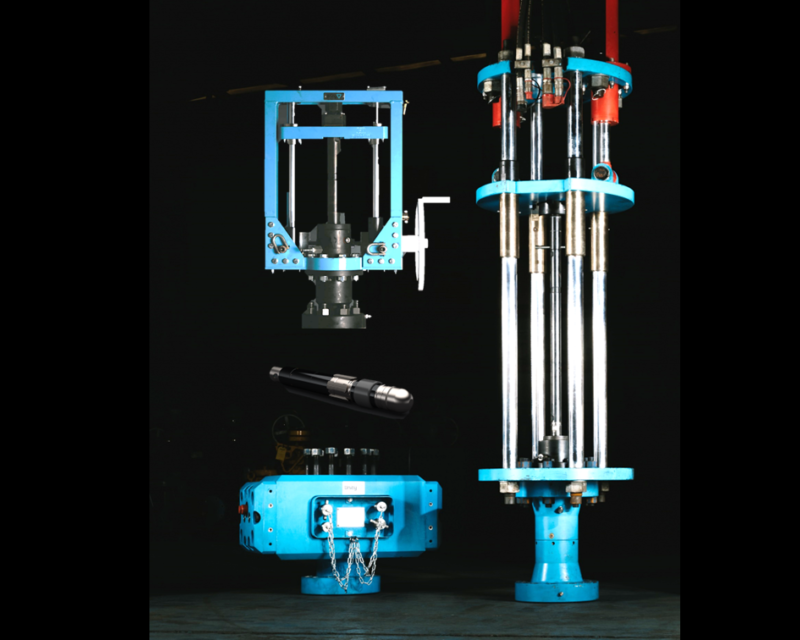

Wellhead support clamp – Prevents excessive vertical movement of the wellhead equipment into the conductor.

Wellhead stabilisation clamp – Prevents excessive lateral movement

Wellhead centralisation clamp – Centralises internal casings within the conductor.

Conductor connector clamp – Secures conductor sections together where connections show signs of parting.

Conductor seal clamp– Prevents water ingress from cracks and splits.

Observation and inspection tool – Wall thickness, visual inspection, dimension checks

Conductor cleaning tool – Uses high pressure water jets to clean excessive marine growth from conductors.

Removal of Xmas Tree, pulling tubing hanger, redress pulling tools.

Installation of suspension cap/ flange assembly, flange splitting, bolt torquing.

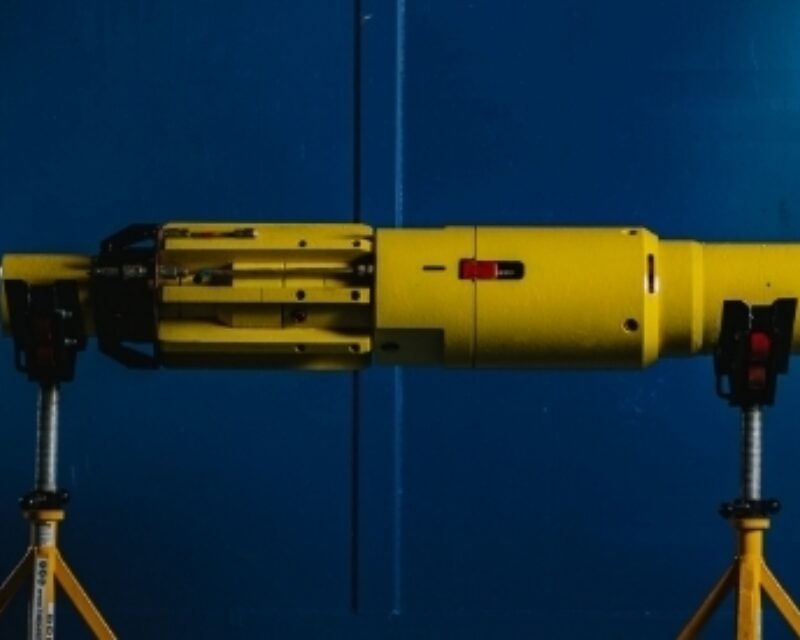

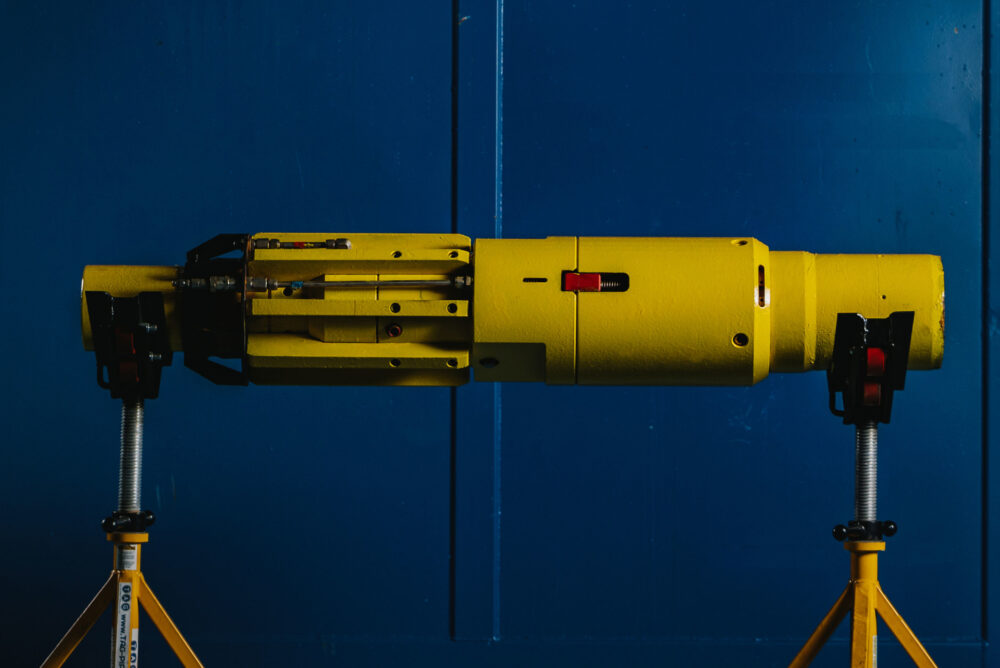

Subsea Decommissioning at Surface Prices

In the high-cost subsea industry, we are experiencing increasing demand for solutions to improve decommissioning efficiency, where small gains provide large savings.

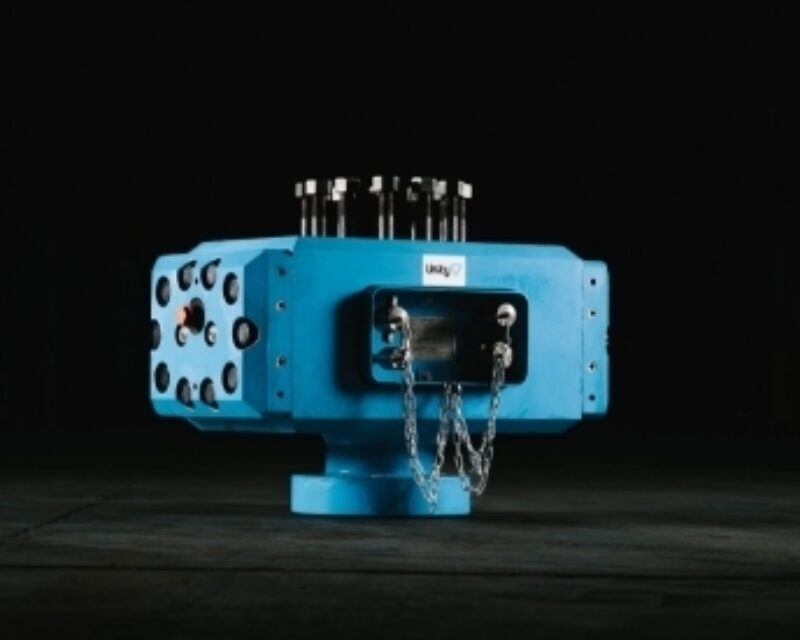

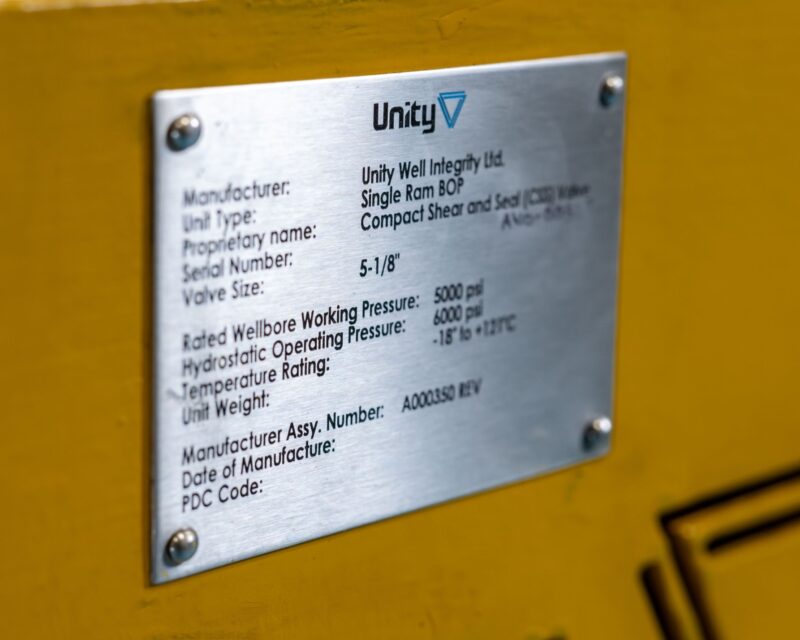

Our range of technology includes subsea actuators, modular shear-seal BOP valves and our Temporary Abandonment Cap Test Tool (TACTT).